As pointed out when this section of the Election blog was first described on the regular blog, I am attempting to highlight how serious some collusion with Russia can be. It is one thing if William Sessions has a conversation somewhere with Russian Ambassador Sergei Kislyak. Democrats on Capitol Hill are seen talking, and even dining, with Mister Kislyak, and no one pitches an hysterical fit over it. In the meantime, our corporations, dating back to the 1920s and continuing to this day, continue to invest in the Russian Military-Industrial Complex. The result of this collusion has been the deaths of over 100,000 American soldiers, Marines, and Air Force personnel in both Korea and VIetnam. It has only been recently that we have finally been taught that our pilots in Korea were actually dog fighting with Russian pilots, who were nicknamed "Honchos" by our pilots. Somehow, our media doesn't care enough about this collusion to tell any of you about it; however, the effects of "trade" with the Soviet Union (Russia) have been documented. Granted, not much about it has "been on television," but just because something is not on television, it does not follow that this must mean that the facts are either: 1. Not true; or 2. Not important.

People have to learn that when corporations are given licenses by the United States Government (USG) to provide the construction materials, production technologies, and the technical assistance in building and maintaining production facilities inside foreign countries that enable them to produce military arms and equipment inside their own borders, the USG is, in its essence, providing the means for that nation to make war upon the United States. It absolutely cannot mean anything else. Just because some Commerce Department, or State Department bureaucrats call such deals examples of "peaceful trade," commonsense argues against such claims in almost every case we will review. This introduction will be put at the beginning of each article in this series to make sure this lesson is finally driven home, if that is possible.

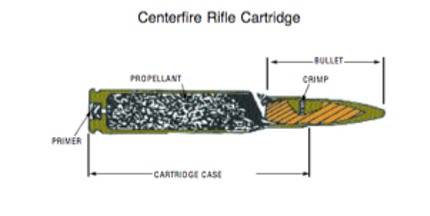

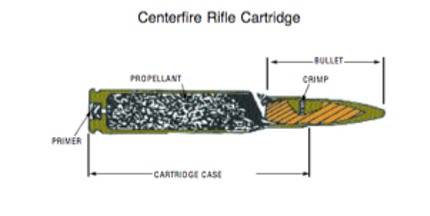

In the early days of firearms, the propellant powder (gun powder) was simple black powder, which is a low velocity propellant. Th powder was loaded separately into the muzzle of a weapon, followed by the projectile that the powder would launch from the barrel, a ball of lead which later became bullet shaped. Beginning in the 19th Century, inventors came up with the cartridge casing and weapons that could fire the cased ammunition. A metallic cartridge casing would contain the powder inside the casing, with the bullet the powder was to launch from the barrel of the rifle inserted into the top of the cartridge casing. A primer cap of fulminate of mercury was embedded in the base of the casing. When the firing pin would strike the cap, the powder would ignite inside the casing, creating the energy to launch the bullet out of the casing and up the barrel of the rifle or pistol. Cased ammunition made semi-automatic and full automatic firing weapons possible, as powder and bullet were stored together in each individual brass or steel cartridge casing. Militaries of the world faced a transition to cased ammunition as a result of the Civil War during which the Union forces began that change from caseless munitions fired from muzzle loading rifled muskets to rifles that took cartridge casings. One Union Army unit, a corps of cavalry and mounted infantry commanded by General James H. Wilson, was entirely mounted on horses and mules, and carried various models of rifles and carbines that fired cased ammunition, including the 16-shot Henry lever action repeating rifle, and the Spencer carbine which used a tubular magazine of cartridges loaded into the butt of the carbine. (1) Wilson's unit was the first rapidly-moving unit that could fight in smaller units because of the firepower each smaller unit could bring to bear on the enemy. Companies could lay down fire in volumes greater than regiments using muzzle loaders, and could use fire-and-movement infantry tactics of today's armies rather than suicidal frontal charges with fixed bayonets.

The propellants used in cased munitions have changed since 1864-1865, when James H. Wilson's all-mounted force invaded Alabama and South Georgia, eventually capturing Confederate President Jefferson Davis, and dealing renowned Confederate general Nathan Bedford Forrest his first defeat at Selma, Alabama. In the last decade of the 19th Century, propellant powders went smokeless. Throughout the 20th Century, the chemical compounds comprising the propellants were being changed to increase the velocity of the bullets in flight. The destructive power of a projectile is controlled by the mathematical equation: KINETIC ENERGY = MASS (WEIGHT OF BULLET) X VELOCITY (SQUARED), OR Ke = M x V2. It is kinetic energy that can wound or kill, along with the debris a bullet can transfer inside a human body, such as bits of clothing, soil, etc. which can cause secondary infections. Bullets leave the barrel of the rifle sterile, but can transfer materials that can cause infections, which is why modern arms almost always create wounds that require surgery on the victims to remove such substances from the wound tracts. Increased velocity can cause more disruptive wounds, particularly when militaries take advantage of higher velocities to use lighter weight in the bullets. Lighter bullets do not always maintain the spin caused by the grooves inside a rifle barrel, particulary the .223 caliber/5.56 milimeter rounds in many assault rifles/carbines. The lighter weight makes the flight of the bullet unstable, and makes the bullet lose its "spin" and even start tumbling. The round travels at speeds that break the sound barrier and trail a shockwave behind them that increases the cavitation produced by the tract made by the bullet through a body. These bullets can also shatter bone beyond repair. This information was to illustrate just how important the ability of formulating the propellant powders inside cartridge casings can be for the modern military. Any assistance in related technologies that are provided through "trade deals" that improve a nation's ability to manufacture such propellants inside the nation's own borders enhances that nation's military-industrial capabilities.

"It is true, of course, that nitric acid is used in the manufacture of munitions."--Excerpt from a letter from Du Pont's management to Henry L. Stimson, Secretary of State, April 20, 1929. The letter was written about a proposed construction of a large nitric acid plant, with Du Pont's assistance, in the Soviet Union (Russia) (2)

What we are going to examine now, in some detail, is how American corporations were able to invest in the Soviet Union's (Russia's) ability to produce the chemicals that go into the manufacture of propellant powders for modern military munitions. The bottom line of this research is that US Corporations, with the approval of the USG through the issuance of export licenses, built the modern Soviet (Russian) ability to produce propellant powders for munitions. The Soviet Union (Russia) provided most of the munitions that North Korea and North Vietnam used to kill our men in two of the hot wars of the Cold War. Therefore, our own corporations and government provided the bullets and shells fired at our own troops.

NITROCELLULOSE FOR AK-47 RIFLE CARTRIDGES

Nitrocellulose is one of the most commonly used propellants in modern munitions. In 1930, the Wilmington, Delaware based Hercules Powder Company executed an agreement with the Soviet (Russian) government for technical assistance in manufacturing nitrocellulose. This deal was approved for export license by the Commerce and State Departments. Hercules Powder sent engineers to Russia to train Russian engineers in the manufacturing process for producing nitrocellulose. Hercules Powder was also committed to hosting three Russian engineers annually in its plants in the United States for periods of three-to-six months. Hercules Powder also had to provide the Russians with complete the complete designs and schematics used to construct their nitrocellulose plants in the United States. The result of helping the Soviet Union (Russia) produce large quantities of nitrocellulose was the Soviets (Russians) being able to produce the mass quantities of cartridges for all of their 7.62 millimeter small arms, including the renowned AK-47 rifle, used against our troops in Vietnam. (3)

NITRIC ACID FOR "PEACEFUL" EXPLOSIVES AND ROCKET PROPELLANTS

One of the ways to get an export license for plants built with U.S. technology in the Soviet Union (Russia) was to remind USG officials that nitrogen compounds, such as nitric acid, are used in manufacturing fertilizers. Nitric acid is also an essential chemical in the manufacture of modern explosives. In the days of Tsarist Russia, the Russians could only produce small amounts of nitric acid, and other countries were also limited in the production of nitric acid. In the 1920s, the United States achieved a break through in the production of synthetic ammonia, which lowered the cost of producing large amounts of nitric acid. Du Pont expended some $27 million in the 1920s to develop their manufacturing of synthetic ammonia and nitric acid. By the early 1930s, the Soviets (Russians) sought assistance from Du Pont in further developing Soviet (Russian) nitric acid production. Entire plants for nitric acid production had already been constructed in the Soviet Union (Russia) by Casale and Nitrogen Engineering Company. The stated purpose for all of these manufacturing facilities was claimed to be the production of fertilizers; however, fertilizer plants can be easily redirected to the manufacturing of propellants and explosives, such as ammonium nitrate, allegedly used in the bombing of the Murrah Federal Building in Oklahoma City and was used by the Russians in the warheads of their T-7A rocket. (4)

In 1932, Du Pont built a gigantic nitric acid plant in the Soviet Union capable of producing 1,000 tons of nitric acid per day, or approximately 350,000 tons annually. Such deals had to be approved by the Commerce and State Departments of the USG. Du Pont was candid about the large capacity of the nitric acid plant by stating in a letter to the State Department that "the excessively large capacity contemplated leads us to believe that the purpose (of the nitric acid plant) is a military one." (5) Well, of course Du Pont would be able to deduce this use for its plant inside the Soviet Union (Russia) as two-thirds of all nitric acid production in the United States was for explosives and munitions. In addition to all of the technology used in building the nitric acid plant for the Russians, Du Pont was obligated by the contract to provide training and technical assistance to the Russians. The State Department approved the construction of the plant in Russia. Du Pont built four other plants in the Soviet Union (Russia) as well.

The processes for manufacturing synthetic nitrogen were exported to the Soviet Union (Russia) by Nitrogen Engineering Corporation (Nitrogen Engineering). Nitrogen Engineering built two large plants in the Soviet Union (Russia), in Bereniki and Bobriki. The plants produced thermite, powder, and nitroglycerin. All of the listed products manufactured by Nitrogen Engineering technology inside the Soviet Union (Russia) have military applications.

RESULTS OF THE "TRADE" DEALS

The transfer of US technology to the Soviet Union (Russia) during the Cold War and the 1920-1930s period contributed to construction of the Soviet (Russian) military-industrial complex's ability to manufacture military munitions, explosives, and rocket propellants and warheads that were used against our own men in Korea and Vietnam. Those policies continued intact throughout the Cold War period.

|

|

There seems to be a division of labor between Western Europe and the United States in arming the Soviet Union (Russia) during the Cold War. The Russians rely more on Western European countries for technology used in the manufacturing of small arms, while relying on the United States for the propellant powders used in the cartridges fired out of those weapons. With machine guns, the Soviets (Russians) relied a lot on Great Britain, Germany, and France. Russia copied part of the German Sturmgewehr (Assault Rifle) 44 to produce the celebrated AK-47 assault rifle as indicated by the photographs at the top of this paragraph.

The US and Western European countries, such as France, Germany, and the UK provided the technology and expertise to build up Soviet (Russian) machine gun production from the 1930s through the Cold War. The French sent machine gun experts to Russia in the 1930s, providing the means for the Soviets (Russians) to produce the Shvak class machine gun used in Russian fighter planes. The Shvak is a varient of the French Berthier.

Russian machine gun and small arms designers became skilled in reverse engineering and tweaking US and Western European machine guns to incorporate simplicity of design, rugged durability, and other capabilities that are preferred by most common infantrymen in almost every army in the world. This approach was particularly successful for the Russians in the production of the AK-47, which is used by many of the world's armies. An AK-47 can keep firing even after being terribly abused or neglected. The Russian weapons designer Kalashnikov produced a Russian machinegun that had a selector switch that could change the cyclic rate of fire of the machine gun.

The Goryunov machine gun is a hybrid of American, German, and British designs. The bulk of the machine gun was a copy of a weapon designed by John M. Browning, one of the United States' most renowned gun designers, responsible for the standard .30 caliber and .50 caliber machine guns still in use by the US Army, and the Model 1911 .45 caliber semi-automatic Colt pistol. The Russians incorporated a Mauser (German) extractor and ejector and a Vickers (British) feed. The Russians directly copied the Model 1910 Maxim (German) machine gun, and often attached it to a two-wheeled carriage.

THE UNITED STATES APPROVES INJECTIONS OF U.S. TECHNOLOGY INTO THE SKODA WORKS IN COMMUNIST CZECHOSLOVAKIA

During the Vietnam War, the Johnson Administration approved a deal between Czech weapons manufacturer, the Skoda Works, located in Pilsen, Czechoslovakia, and the Simmons Machine Tool Company of Albany, New York. Czechoslovakia was a member of the Soviet (Russian) alliance called The Warsaw Pact, which was created to deter the North Atlantic Treaty Organization (NATO) alliance of the US and Western Europe. Skoda was a main weapons director for the Russian alliance nations, with several of its weapons systems going to North Vietnam to help kill our own men during the Vietnam War. Skoda also contributed to the manufacture of the Russian MIG-21 fighter plane. In the agreement with Simmons Machine Tool Company, the Skoda works were to produce machine tools designed by Simmons Machine Tool Company. These machine tools were critical in the manufacturing of armaments, including small arms, machine guns, and artillery pieces. The following machine tools were produced by Skoda uner the Vietnam War-era deal with Simmons Machine Tool Company:

The Western European and American corporations who supplied such technology ahd to know it had military applications, since we use the same technology, supplied by the same corporations, to make weapons for our military. Make of that what you will.

(1). Starr, Stephen Z.: The Union Cavalry in the Civil War, Volume III--The War in the West 1861-1865, Louisiana State University Press, 1985.

(2). Sutton, Antony: National Suicide: Military Aid to the Soviet Union, Arlington House, 1972.

(3). Sutton, Antony: National Suicide: Military Aid to the Soviet Union, Arlington House, 1972.

(4). Sutton, Antony: National Suicide: Military Aid to the Soviet Union, Arlington House, 1972.

(5). Sutton, Antony: National Suicide: Military Aid to the Soviet Union, Arlington House, 1972.